Special Purpose Machine:

In-Depth Features:

Bearing Industry solutions:

Our special purpose machines for the bearing industry are meticulously designed covering a spectrum of bearing types. Such as:

1. Angular Contact/Ball Bearings

2. Taper Roller Bearings

3. Cylindrical Roller Bearings

4. Spherical Roller Bearings

5. Thrust bearings.

Our Grinding solutions with Automation and part transfer capabilities optimize production processes, ensuring efficiency and consistency. A complete line with integrated Honing machines and Post process gauging solutions under a single roof means you will never have to look anywhere else for your bearing production.

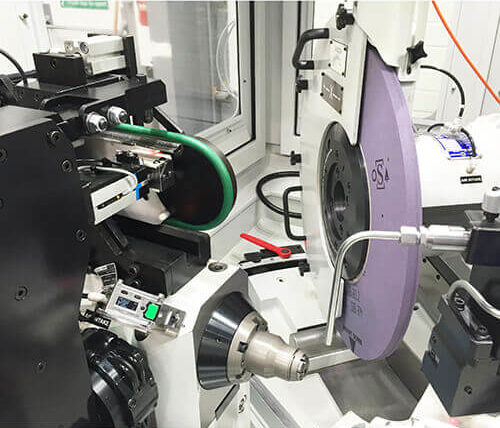

Engine Valve Solutions- Versatility Redefined:

Beyond the bearing sector, SANBERG’s offerings span engine valves, valve seat grinding, stem end cut off, groove grinding, and more. Customizable solutions meet the unique demands of each industry, showcasing the adaptability of our machines.

1. CNC Valve Seat Grinder / 80mps world class machine

2. Stem End Grinding

3. Stem Dia Grinding/Centreless

4. Stem end cutoff machine

5. Groove Grinding machine

6. Head cutoff machine

7. Bar Chamfering Machine

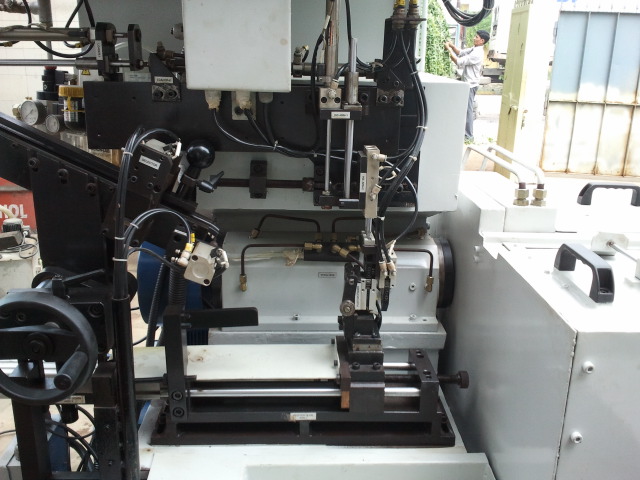

Die Casting for Pistons:

Our expertise extends to die casting machines for pistons casting for both gasoline and diesel, featuring twin cavity, single cavity, and four cavity designs comes with auto unloading feature. Robot integration facilitates automated pouring and unloading, streamlining the intricate process of piston manufacturing.

1. Single Cavity Die Casting Machine

2. Twin Cavity Die Casting Machine

3. Four Cavity Die Casting Machine

4. Multi Oil hole drilling machine

SANBERG’s Special Purpose Grinding Machines stand as a testament to our engineering prowess, providing comprehensive solutions for a multitude of industries. Dive into a world where precision meets versatility, setting new standards in specialized machining.